- 10 Marks

Question

Plytimba manufactures high-quality wooden chairs using odum sourced from sustainable forests. The company began trading two years ago having identified a niche market for the product.

During the year, Plytimba was forced to purchase wood from a different company as the usual supplier did not have sufficient stock available. The company operates a standard variable costing system and details relating to the most recent financial period are shown below.

Budgeted Information:

- Production in units: 134,400

- Direct materials: 10,080 square metres odum wood = GH¢282,240

- Direct labour: 33,600 hours = GH¢483,840

- Variable production overhead (based on direct labour hours): GH¢225,792

- Fixed production overhead: GH¢29,200

Actual Information:

- Production in units: 135,000

- Direct materials: 10,800 square metres odum wood = GH¢300,240

- Direct labour hours: 27,000 hours = GH¢486,000

- Variable production overhead: GH¢194,400

- Fixed production overhead: GH¢30,150

Required:

i) Prepare a Standard Cost Card for one wooden chair. (4 marks)

ii) Calculate SIX (6) variances in as much detail as the information above permits. (6 marks)

Answer

i) Standard Cost Card for One Wooden Chair:

| Cost Component | Per Unit Calculation | Per Unit Cost (GH¢) |

|---|---|---|

| Direct Materials | 10,080 sq. m / 134,400 units = 0.075 sq. m per unit | 0.075 x 28 (GH¢/sq. m) = 2.10 |

| Direct Labour | 33,600 hrs / 134,400 units = 0.25 hrs per unit | 0.25 hrs x 14.40 (GH¢/hr) = 3.60 |

| Variable Overhead | 0.25 hrs x (225,792 / 33,600 hrs) = 1.68 | 1.68 |

| Total Cost Per Unit | 7.38 |

ii) Variances Calculation:

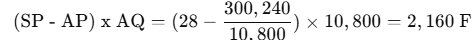

- Direct Material Price Variance:

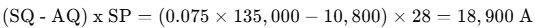

- Direct Material Usage Variance:

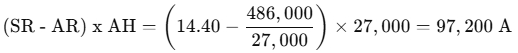

- Direct Labour Rate Variance:

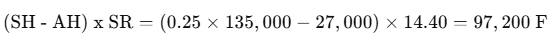

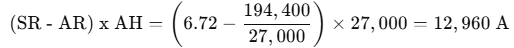

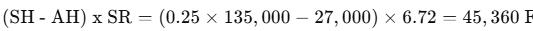

- Direct Labour Efficiency Variance:

- Variable Overhead Expenditure Variance:

- Variable Overhead Efficiency Variance:

- Fixed Production Overhead Expenditure Variance: BFO – AFO=29,200−30,150=950 A

- Tags: Labor Variance, Material Variance, Overhead Variance, Standard Costing, Variance Analysis

- Level: Level 2

- Topic: Standard Costing and Variance Analysis

- Series: APR 2023

- Uploader: Joseph